POWERPLASMA 102I

The PowerPlasma 102i is designed for heavy duty plasma cutting service. With up to 100 amps of cutting power, the original unit has proven its performance and reliability in industrial and fabrication settings since 2008. The IGBT inverter design is reliably engineered to provide heavy duty service with a 60% duty cycle at maximum amps. This is enough to sever metal up to 1 5/8″ thick when needed. For daily use, it works great for regularly cutting 1 1/4″ thick plate metal, and when called upon, makes a clean cut up to 1 1/2″. The heavy duty Innotec IPT-100 blow back torch features a Euro, quick connect central adapter for easy connection.

The machine is therefore suitable for the field even if long hangs are used and the electricity is of poor quality.

POWERPLASMA 102i is fully CNC compatible including machine controlling plug and can optionally be equipped with straight CNC torch (sold separately here).

A reliable machine for both enthusiasts and professionals.

The European unit’s is 3 phase 400V.

€2.153,00 inc. VAT

Stock level:

In stock.

Warranty: 2 years

TECHNICAL DATA

Type: IGBT

Voltage/phase: 380V 3 Phase

Duty Cycle At Rated Amps/Volts: 100A max 60%

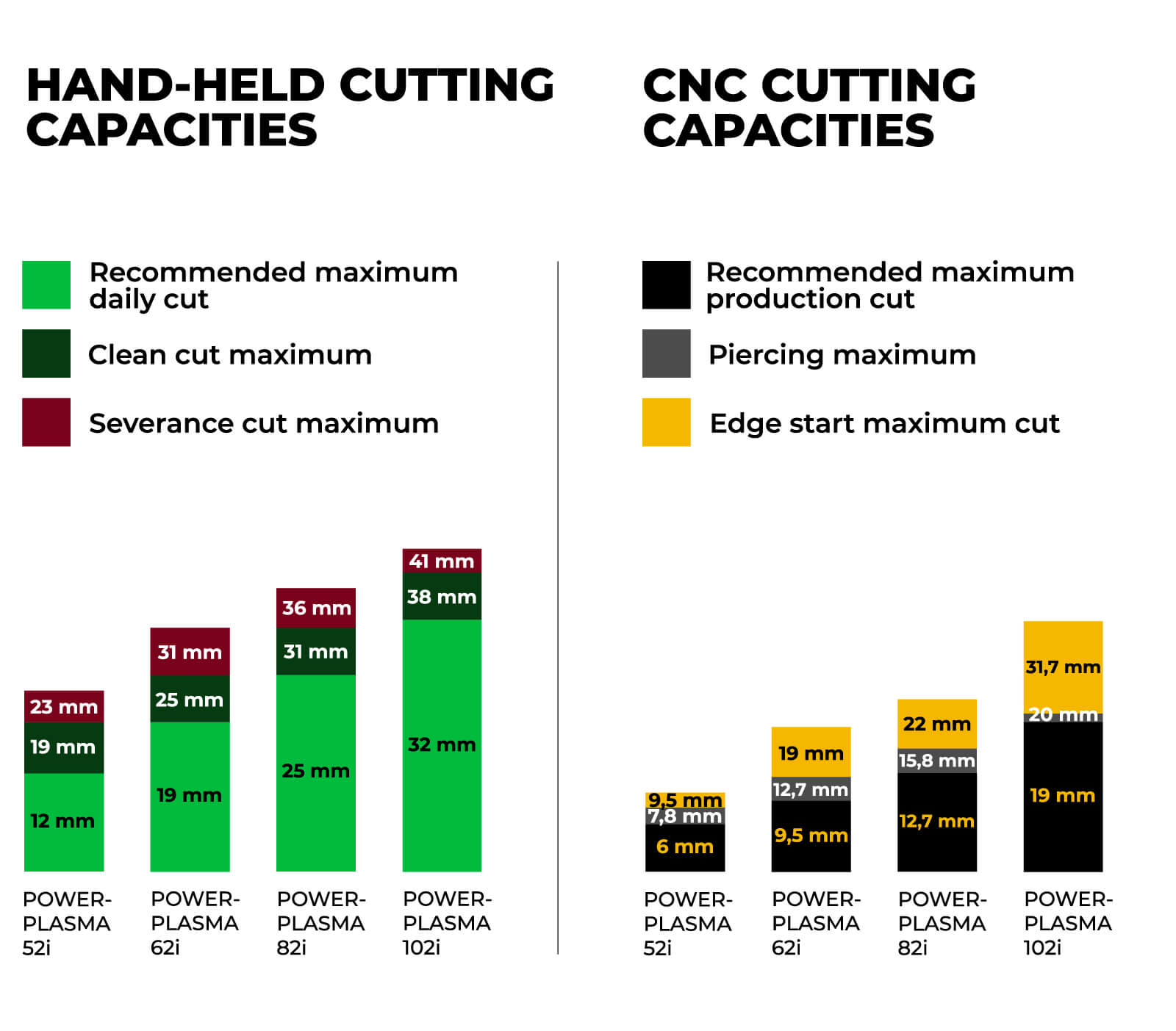

Cutting capacity: recommended up to 32 mm, maximum clean cut ~ 38 mm (mild steel), CNC maximum piercing capacity is 20 mm

Arc Start Type: Blow Back (Piston type)

PilotArc: Yes

CNC Interface Port: Yes

Adjustable Post Flow Timer: No

Gouging: Yes

Torch Type: Genuine Innotec iPT100

Recommended Cutting Air Pressure: ~ 350L / min 4.5-5 ba

OK-to-Cut Indicator/Low Air pressure safety: No

Dimensions: 56 cm × 23 cm × 43 cm

Weight: 26 kg

OPTIONAL: Can be fitted with CNC torch (sold separately here)

DESCRIPTION

A reliable machine for both enthusiasts and professionals. The machine is a 400V 3-phase and is therefore suitable for the field even if long hangs are used and the electricity is of poor quality.

Thanks to the pilot arc ignition, cutting is easy even for a beginner, and even tight spaces are out of reach.

The machine has an A101 burner as standard. The machine is also equipped with a CNC connection.

The PowerPlasma 102i is designed for heavy duty plasma cutting service. With up to 100 amps of cutting power, the original unit has proven its performance and reliability in industrial and fabrication settings since 2008. The newest version has been redesigned for a more compact stature. The IGBT inverter design is reliably engineered to provide heavy duty service with a 60% duty cycle at maximum amps.

- Easy starting with Blow Back Pilot arc allows easy cutting of rusty and painted metals

- Cuts virtually any type of metal with ease

- Simple to use torches with inexpensive service parts and consumables

- Commercial class, 60% Duty cycle at 100 amps

- Clean, smooth cuts with the genuine Innotec iPT100 torch.

- Pilot arc improves performance and cutting on dirty, painted, or rusted metals

- Front air pressure gauge allows quick verification of air pressure

- Over Current and Duty Cycle protection indicates fault with a dedicated warning/diagnostic light, and shuts down output until condition is resolved

- IGBT modules improve reliability and performance while reducing overall weight

- CNC socket for CNC use on plasma tables (machine torch optional)

- Industrial Fabrication

- Pipelines

- Shipyards

- Motorsports facilities

- Repair shops

- Rail Road maintenance

- HVAC

- Heavy Equipment Repair

- Farm/Ranch

DOWNLOADS

PRODUCT NOTES

A separate air dryer must be provided by the customer to prevent torch damage, and excessive consumable wear. The unit includes a regulator/water trap, but is not designed to remove all water or moisture. Contact Everlast directly for Special orders with alternative voltages and phases. Additional charges may apply. Contact Everlast directly to order special units. Allow 6-8 weeks for special order deliveries.

MINIMUM/MAXIMUM

Plasma cutting capacity is affected by several factors. Ideal cutting conditions require dry air, new consumables, proper air pressure etc. Quality of cut depends upon consumable orifice size, standoff height, and travel speed.

CNC cutting capacity is calculated for a quality cut at 100% working cycle. Cutting near maximum piercing capacity shortens consumables life span. Cutting thicker materials than maximum piercing capacity is possible but requires edge starting.