POWER I-MIG 253DPI

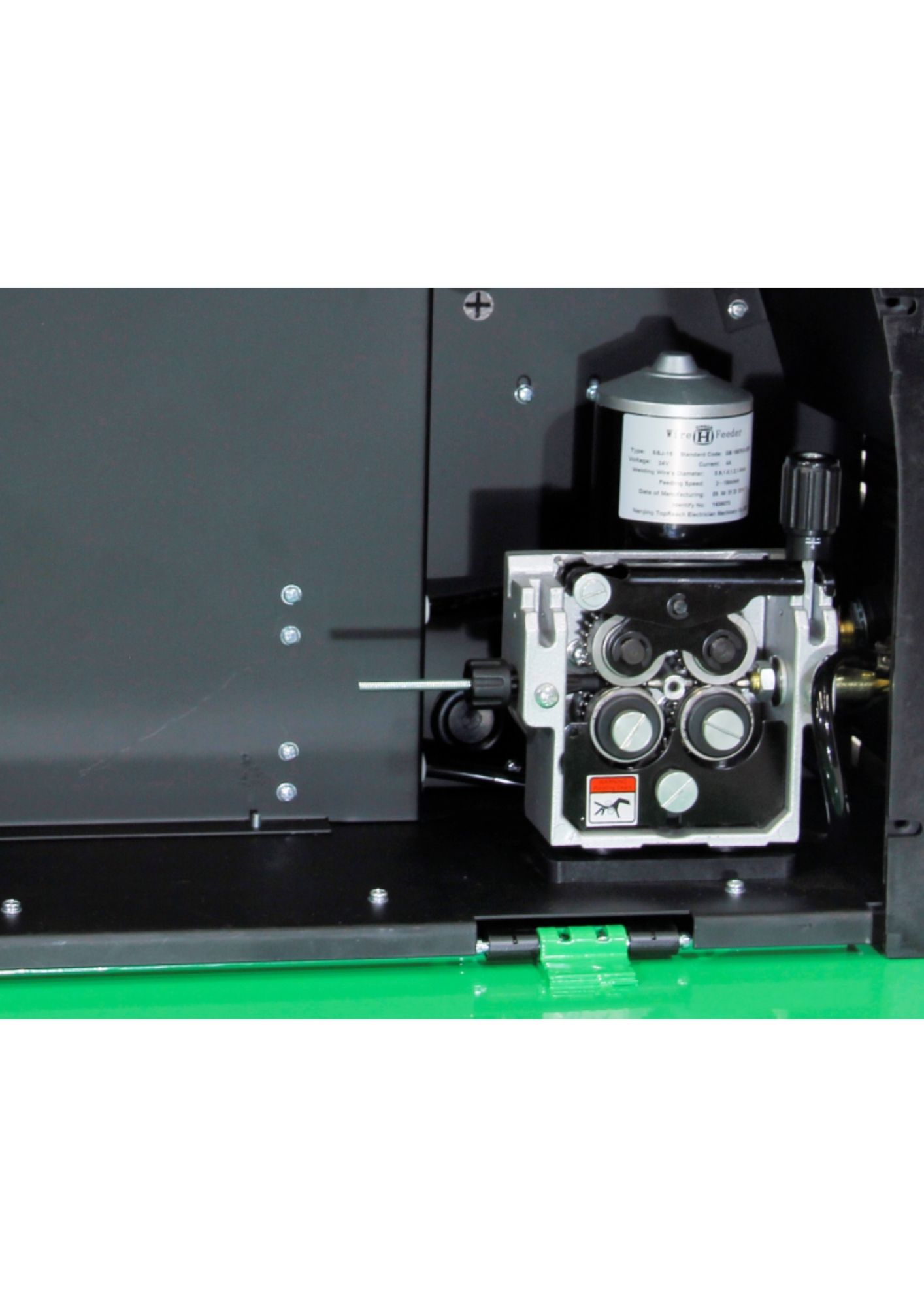

The Power i-MIG 253DPi features the latest in inverter based, pulse MIG technology. This welder is ideal for welding aluminum and bronze brazing activities in the automotive industry. It features two types of synergic pulse: Single and Double. The Single Pulse is perfect for control heat and wet in and burn through of heat sensitive metals where HAZ issues are a concern, such as the auto-body businesses where new alloys require special welding and brazing processes to repair frames and panels safely and reliably. With Single pulse, increased production speed welds are possible without over-melting or the metal, allowing for out of position welding of aluminum. Double pulse features a “stair-stacked” pulse which features the ability to stack the single pulse into two basic layers, which helps to form a “stack of dimes” TIG look in the weld. This is ideal for welds where appearance and strength count equally and is required for best possible appearance without resorting to TIG. The unit can also be used in a synergic MIG mode without pulse and a basic non-pulse, non synergic mode as well, where full control over all parameters are possible manually. To prevent crater cracking and cold starts the unit has several features which include slope up, hot start, down slope. Pre and post flow are standard features as well, which help prevent porosity at the beginning and end of welds where it is common to develop weld flaws. If you find a program you like in a manual setup mode, you can easily save it with the capacity to store 9 major programs. The unit is programmed with a possible 40 different, well designed and tested synergic programs for standard and pulse MIG operation. Companies and individuals who are looking for the consumate professional MIG machine will appreciate the ability to fine tune the arc even while in synergic mode, a hallmark characteristic of all Everlast synergic capable MIGs. The Power i-MIG 253DPi brings the price significantly down from competitor models, making this one of the affordable and capable pulse MIG welders on the market. There’s no longer any need for a company or individual to spend $10,000 or more on a special welding machine to repair modern alloys. The machine can be used to weld aluminum, bronze, steel, or stainless. When welding aluminum, the standard gun works well, but an optional spool gun or push-pull gun can be used to feed wire from .030″ to .045″ in diameter using the syngeric pulse feature. The 60% duty cycle at 250 Amps proves this unit is a serious heavy-weight contender. If you really want to compare to other units in this class, check out other manufacturer’s duty cycle at maximum output. Some can only operate at maximum output for 10 seconds. Others are only at 10% at maximum output.

Attention buyer!!

USA and Europe packaging is slightly different!!

The European package does not include the throttle.

€2.332,00 inc. VAT

Stock level:

in stock

Warranty: 2 years

TECHNICAL DATA

Type: Digital/Micro-controlled IGBT Inverter

Output /Process Type: MIG, Stick

Voltage/phase: 400 V 3 Phase

Max Rated MIG Amps: 250A

Max Rated Stick Amps: 250A

MIG Amps/Volts @ Rated Duty Cycle:

250A/26.5V @ 60% Duty Cycle/ 40º C

200A/28V @ 100% Duty Cycle/ 40º C

Stick Amps/Volts @ Rated Duty Cycle:

250A/26.5V @ 60% Duty Cycle/40º C

200A/28V @ 100% Duty Cycle/40º C

Max Inrush ( I1MAX ) Amps: 45.5A

Maximum Rated (I1EFF ) Input Amps: 36A

OCV: 80V

MIG Output Range: 40-250A/ 16-30V

Stick Output Range: 10-250A/20.4-30V

Variable MIG Inductance/Stick Arc Force Control: Yes

Spool Gun Capable: Yes

Pulse: Double/Pulse on Pulse

Pulse Frequency: 10-250 Hz Single Pulse Mode

0-9.9 Hz Double Pulse

Pulse Time On: Synergically controlled

Pulse Volts: Synergically controlled, with Voltage offset

Standard Drive Roll wire size: .030”-.045”

Separate wire feeder: No, self contained

Number of Drive rollers: 4

Max Wire Feed Speed: 600IPM

Max Wire Roll Diameter: 12” (full size up to 44lb)

Memory: Yes

Preflow time: 0-10S

Post Flow Time: 0-10S

Flux Core: Yes, Optional

2T/4T /Torch latch/Trigger: Yes

Other Features: 9 Program Memory

Stick mode

Spool gun and Push pull gun capability

Hot Start Time 0-2 Seconds

Hot Start Intensity 0-100%

MIG Inductance 0-100%

Synergic and Manual basic MIG modes

Synergic Single Pulse and Double Pulse MIG modes

Extra Drive Rolls included .023″-.045″ Hard Wire

1 Aluminum drive roll, .035″ and .045″ (nominal diameter) and poly liner for 50XX wires.

Burn Back Control 0-2 Seconds

Synergic Pulse

DESCRIPTION

DOWNLOADS

PRODUCT NOTES

If running on a generator, make sure the generator is rated by the generator manufacturer as providing “clean power”, which is 5% or less THD (Total Harmonic Distortion). Failure to do so may result in failure of the unit. Use with any generator not labeled as clean power wil void the warranty on the affected parts. Use with a minimum of 11,500 Watt generator. Do not use long or underated extension cords with this unit.

This unit is not designed to weld with E5010 welding rods.

MINIMUM/MAXIMUM

- Weld up to a maximum of 7/16″ Steel/Stainless single pass

- Weld over 3/4″ Steel/Stainless multi-pass

- Weld a minimum of 27 gauge Steel/Stainless (Pulse mode)

For MIG welding Aluminum, use the supplied 10 ft MIG gun, U-groove drive rolls and the polymer liner (best choice for shorter distances). For longer required distances, choose between the Parker SG360A Push-Pull Gun (Recommended for longer distances) or the Parker DSP 360 (Recommended for small weld quantities/longer distances) For Brazing, follow same recomendations for gun selection.

- Weld up to a maximum of 3/8″ in a single pass weld Aluminum

- Weld over 3/4″ in multiple pass welds Aluminum

- Weld a minimum of 24 Gauge Aluminum (Pulse mode)

For Brazing with MIG:

- Braze down to a minimum of .025″

- Upper practical limit is 3/16″-1/4″ for the Brazing Application

Stick:

- Weld up to a maximum of 5/32″ diameter electrode

- Weld with a minimum of 1/16″ diameter electrode